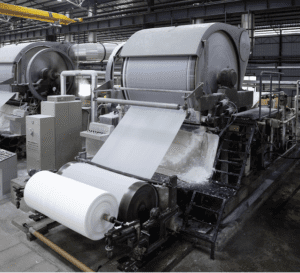

Paper and Pulp Partners

The Paper and Pulp industry demands reliable flow control products that can handle corrosive liquids with little to no maintenance or downtime. Valveforce’s expertise can tailor your needs to suit your system requirements.

Valveforce is a focused company that is an expert in providing independent technical advice for steam, condensate and specialist process valves, to suit hazardous, corrosive, high pressure and abrasive environments.

A Name You Can Trust

The Paper and Pulp Industry have long runs and need uninterrupted services so that production can go on as scheduled without costly valve failures that could shut down the process.

As an independent supplier of soundly engineered valves, controls and services to the Paper and Pulp Industry, Valveforce has established itself as a name you can trust for sizing and selection of valves and controls for your applications.

“Our qualified technical engineers have a wealth of experience in working with our customers to provide long term solutions in process control.”

Save with the right valve type for your application

Our excellent relationships with a variety of established valve manufacturers, particularly for arduous and severe applications, enables us to offer you a comprehensive range of valves to suit your application and reduce your costs.

A paper mill, for example, working closely with us can make significant savings in their valve selection through the introduction of uniformity, interchangeability and a reduced spares stock holding.

In addition to the consultation design and supply of equipment, Valveforce is capable of installation, commissioning, service, maintenance, overhaul and repair.

The Complete Valve Package

Partnering with Valveforce means that you have one point of contact for all your valve needs:

- Design

- Specify

- Supply

- Install

- Commission

- Service

- Maintain

- Repair

Numerous Applications

The Paper and Pulp Industry has numerous applications for high quality valves, especially high-performance butterfly valves, ball segment valves and rotary control valves. This is because steam applications are used for the production of chemical market pulps to making high quality stock.

In corrugating machines, steam is used to provide heat which is necessary in the forming, bonding and conditioning processes.

Ball segment valves with stellite seats are used in the stock preparation area where abrasive contaminants are often found.

Screening Process and Stock Dosing Areas

In the screening process and stock dosing areas will use ball segment valves but with a more standard PTFE seat; blow line valves, liquor circulation valves, pulp flow valves. This is also a requirement for the screening and bleaching plant.

Where additives are added to the application, they can become arduous so particular attention should be paid to the valves in this area as often hard faces are required or even ball sector valves with ceramic inserts.

Safety

Safety compliance is paramount and Valveforce can easily control and maintain these high standards by our experts selecting the appropriate valves. Often there are applications where throttling differential pressure is high; Valveforce understands these applications and will specify a ball segment valve with a unique low trim to break down the pressure gradually. This will eliminate the problems with noise cavitation and erosion.

Vacuum Service

In a vacuum service pipe dimensions are often large, so a high-performance butterfly valve is the most economical final control element. The same applies to the large pipe dimensions in screening, centricleaning and where stock consistency is below 5%.

High performance butterfly valves are also used as steam control and mains isolation.

For general isolation of water systems and compressed air lines we stock a comprehensive range of knife gate and wedge gate valves.

At Valveforce we have capabilities to aid the Paper and Pulp Industry with their most demanding valve and flow control valve problems.

Whether you need to find a cost-effective globe control valve in stock for same day despatch or a ceramic lined ball segment valve for very arduous and aggressive media, Valveforce are here to help.

Valves we provide to the Paper and Pulp Industry:

- Rotary Control Valves

- High Performance Butterfly Valves

- Segmented Ball Valves

- Linear Knife Gate Valves

- Intelligent Controls to Optimise Performance

- Steam Temperature Control Valves for Corrugating Machines

- Condensate Recovery Systems

- Steam Traps

Valveforce Project Services

Audit and Design Work

- Independent Steam Systems Audits

- Heat and Energy Loss Insulation Audits

- Boiler BG01 and Water Treatment Audits

- Detailed Consultancy and Design Specification

Service Agreements

- Boiler House Service Agreements

- Heat Exchanger Service Agreements

- Flow Metering Service Agreements

- Control Loop Service Agreements

- Plate Heat Exchanger Service Agreements

Survey and Testing Work

- Comprehensive Steam Trap Surveys

- High Temperature Protection Surveys

- Safety Valves In Situ and Off Site Testing

- Valve Repair and Testing

- Swap Out and Full Installation Site Works

Wish to make an enquiry? Need Support? ...or Have a Question? Speak with our Valve experts... Click Here

Download the latest Valveforce brochure here