Condensate Recovery Pump Systems

At Valveforce, we are experts in the field of steam engineering and condensate recovery pump systems. We can offer real value to our customers in factories and hospitals. As well, we have vast experience in designing, supplying and installing steam distribution, steam pipe installation and condensate recovery systems.

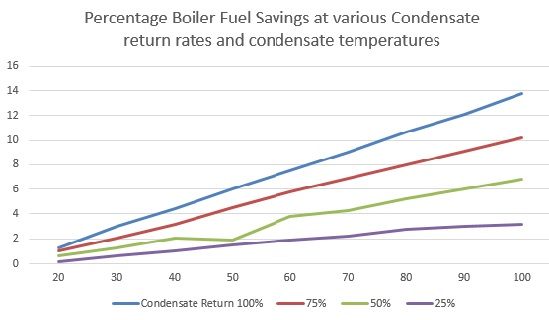

Condensate Pump Sets Energy Savings

Valveforce’s Condensate Recovery Pump Systems & Pumping Sets

- Type CRO Condensation Pumping Set with On/ Off Controls

- Valveforce’s stainless steel until provides a simple, effective and reliable method of collection and returning condensate to the boiler feedtank or hotwell.

- The Units are compact requiring minimum of floor space and headroom

- Designed to handle and pump condensate at temperatures up to 98°C for maximum heat recover

- Stainless steel collecting vessel for long corrosion free life

- Well proven solid state level control equipment as used on steam boilers. There are no moving parts so there is nothing to wear or stick

- Automatic standby pump for uninterrupted working

- Construction packaged unit

- Stainless steel condensate vessel

- Our condensate tanks are stainless steel, therefore, they do not require maintenance associated with the Coated, Galvanized or Zinc alternative. They can withstand temperatures above 80 °C. Stainless steel tanks have high strength, durability and corrosion resistance even at high temperatures.

Pipework and Fittings

The unit comes complete with integral suction pipework, isolating valves for pumps, non-return valve at pump discharge and modulating control valve in the discharge manifold.

Solid State Level Electrode

The capacitance electrode has no moving parts in the vessel, giving you:

- Trouble-free operation and low maintenance

- Modulating control band

- Pump on-off control

- Low and high level alarms (optional)

- LED 'bar chart' display of water level (optional)

On/Off Valve

Pumps Duplicate vertical centrifugal pumps with stainless steel impellors and 3ph, 415V, 50 Hz motors as standard.

Control Box

The control equipment, pump contractors and other accessories are provided in a tough lockable steel enclosure giving protection to IP55 and ready for wall mounting. Pump selector switch, indicating lights, auto-changeover with warning lamp are included as standard on double pump units.

Principle of Operation

The pump output is modulated to match the rate of condensate flow from the process plant by means of a control valve on the discharge side of the pump. The pump normally runs continuously, but shuts itself down when incoming condensate flow almost stops. The system restarts automatically as required.

Further savings:

- Savings on lost energy and water treatment – hot condensate is relatively pure water, returning it reduces your chemical treatment requirements

- Reduction on water preheat costs; fuel costs; water effluent costs and make up water costs – every litre of hot water returned saves similar amount of cold make-up water

- Upsurge in boiler efficiency due to high feedwater temperatures

Operation and Maintenance

Fault Checks

Mechanical Seal

Mechanical seal failure is usually indicated by fluid leakage from that area of the pump assembly. The usual cause is dry running the pump, lubrication of the seal being dependent upon the fluid being pumped. Multi-stage condensate pumps have the shaft seal at the top of the casing. They are especially vulnerable if the mechanical seal has not been fully flooded, because of improper pump casing venting.

Fluid Cavitation

Cavitation occurs because of, (a) insufficient pump suction pressure for the liquid (condensate) temperature at the pump suction port. Alternatively, (b) because the condensate flow rate and discharge pressure does not correspond with the selected duty point on the pump performance curve. It could also be a combination of (a) and (b). Simplistically, because there is insufficient suction pressure at the extant condensate temperature, the pressure in the pump casing can reduce sufficiently for the condensate to partly ‘flash’ into a vapour and condensate mixture. The total liquid state of the condensate not being sustainable at the reduced pressure and elevated temperature. The result is commonly known as cavitation. Most mass produced pumps are not designed to reliably handle a fluid in this combined vapour and liquid state.

Cavitation invariably results in excessive operating noise inside the condensate pump. It will ultimately lead to a serious mechanical failure of the pump and/or impeller(s) and should always be eliminated.

If cavitation occurs, the following should be reviewed.

The duty conditions specified for the pump selection and if the correct condensate pumping set model been selected for the actual duty conditions. Whether the actual condensate temperature at the pump suction port is higher than that specified for the pump selected. Is the condensate pump discharge pressure requirement less than that specified for the pump selected?

If the condensate pumps temperature is significantly higher than that specified, check the condensate returns systems for high pressure/temperature condensate discharge from any item of plant and, especially, for faulty steam traps.

If regulating valve sets have been included in the condensate set package, check they have they been adjusted as recommended above. However, if regulating valves have not been included in the condensate set package, consider installing pump discharge flow/pressure regulating valve sets. This will help to control the condensate flow and discharge pressure at the selected pump duty point.

If pump(s) fail to run or there's a motor fault then check:

- main power supply and door interlocked isolator are switched on

- condensate is at high level - pump(s) will not run until high level switch(es)are in a ‘wet’ state, or the float is the ‘high’ position

- pump selector switch position - Duplex pump sets only

- full load current stated on motor plate and overload setting - adjust if necessary

- control circuit MCB or transformer fuses if the control circuit is low voltage -re-set or replace. If repeated tripping or fuse failure occurs, the control system must be fully checked by a competent electrical engineer

- each level control function - pump(s) will only run if both high and low level switches function correctly

- for electrical wiring fault or short circuit condition

- motor windings for integrity and for three phase motors loss of one or more phases

- single phase motors - check capacitor connections and capacitor conditions

Maintenance & Repairs

Only carry out maintenance and repairs with the electrical supply disconnected and not before a set and its fluid contents have cooled to a safe temperature (say below 25oC) and with the set fully isolated from incoming and outgoing condensate flow and pressure.

Duplex sets: if removing a pump for repair or maintenance and the set is to remain operational, the power must always be switched off at the mains supply and the cable terminations made safe before returning a set into service for single pump operation. If a pump requires repair or servicing, contact Valveforce Limited to see how we can support you.

Vibrating fork level control switches are not user serviceable. If a fault occurs to a level switch, contact Valveforce Limited to obtain a replacement switch, or return the entire switch to Valveforce Limited. Float type level control switches are user serviceable but, in certain circumstances, re-setting can be difficult. If a fault occurs, please contact Valveforce Limited to obtain a replacement switch, or return the entire switch to Valveforce Limited. To remove a level control or alarm switch, reduce the condensate level to below the level of the switch before attempting to remove a switch from the vessel. Always immediately replace the removed switch, or plug the removed switch nozzle before returning a set into operational service.

Safety Precautions

Condensate Recovery Systems

- Observe all site safety regulations and recommendations at all times

- Do not leave this equipment unattended with the controls enclosure door open and with the mains supply power switched on

- The open vent and overflow connections must not be fitted with isolation valves and must not be capped or plugged

- Under normal operating conditions this equipment will have hot external surfaces and will contain hot fluid at a temperature approaching 100 oc. do not install in locations, or in such a manner, where unauthorised personnel or members of the public can come into contact the equipment

- Do not work on the installation whilst it is operating under pressure and/or at high temperature. Always ensure the installation and its fluid contents have cooled to a safe temperature and the equipment has been isolated from all incoming or return fluid flow and pressure sources

- Pump(s) must not be operated without water inside the collection vessel and until the pump has been fully filled with condensate, or water and purged of entrapped air. Do not run a pump with a closed suction valve or with an open end discharge pipe, or against a closed discharge valve for more than a few seconds. Never run a pump without water inside the casing and without fully flooding the pump shaft seal

- The equipment should be drained down to a safe location only and only when the fluid has cooled to the maximum

- Allowable temperature for the drainage or sewerage system

Condensate Recovery Pump Sets

- Stainless steel atmospheric collection vessel with electric pump sets

- Duty and cascade pump control for efficient recovery of valuable condensate

- Condensate pump sets pre-fabricated and robust in design for reliable long life

- Stainless steel atmospheric collection vessel with electric pump sets

- Duty and cascade pump control for efficient recovery of valuable condensate

- Condensate pump sets pre-fabricated and robust in design for reliable long life

Wish to make an enquiry? Need Support? ...or Have a Question? Speak with our Valve experts... Click Here

Download the latest Valveforce brochure here